Liquefied natural gas (LNG) is liquefied natural gas by refrigeration for non-pressure storage or transportation convenience and safety. LNG mainly contains methane. When natural gas is liquefied, its volume decreases 600 times. LNG is odorless, colorless, non-toxic and non-corrosive.

The gas generated from hydrocarbon beds contains a wide variety of hydrocarbon products, usually including methane (CH4), ethane (C2H6), propane (C3H8) and butane (C4H10). A gas flow is provided by cleaning “acidic” elements such as hydrogen sulphide (H2S) and carbon dioxide (CO2), oil, sludge, water and mercury. Failure to separate or remove such acidic molecules, mercury and others will result in equipment damage. Corrosion of steel pipes and as mercury mixed into aluminum in cryogenic heat exchangers can cause costly damage.

Methane, ethane, propane and butane in the natural gas are separated. Butane and propane are used for Liquefied Petroleum Gas (LPG) or its fractions. The methane and ethane fractions are liquefied to form the bulk of the LNG.

Locations where pipelines are unsuitable, such as places where gas-producing oil or gas fields are far from pipelines or on the high seas, were considered economically unimportant for natural gas. In the past, this meant that the natural gas produced was typically flamed. In particular, unlike oil, there was no suitable method such as pipelines, natural gas storage or transportation facilities that would allow this gas to be used immediately by its end users.

Over time, technological possibilities in production processes, developments such as cryogenic storage and transportation enabled natural gas to compete with other fuels in the global market and to commercialize it. The development of LNG storage has become reliable even for situations that were previously thought to be impossible.

History

Experiments on the properties of gases began in the early 17th century. In the mid-seventeenth century, Robert Boyle derived the inverse relationship between pressure and gas volume. Around the same time, Guillaume Amontons began researching the effects of temperatures on gas. Various gas experiments continued for 200 years. During this time, there have been efforts to liquefy gases. Many new facts have been discovered about the nature of gases. A number of scientists such as Michael Faraday, James Joule, and William Thomson (Lord Kelvin) have experimented in this area. In 1886, Karol Olszewski liquefied methane, the main component of natural gas. In 1900, all gases except helium, which was liquefied in 1908, were liquefied.

The first large-scale liquefaction of natural gas in the US occurred in 1918 when the US government liquefied natural gas as a way of separating helium, a small component of some natural gas. This helium was designed for use in British zeppelins for World War I. Liquid natural gas (LNG) was not stored, converted to gas and supplied directly to the gas grid.

In 1915, Godfrey Cabot patented a method for storing liquid gases at very low temperatures. In 1937, Lee Twomey patented a process for the large-scale liquefaction of natural gas. The aim was to store natural gas as a liquid. Because of the large volumes, it was not practical to store natural gas as a gas close to atmospheric pressure. However, when liquefied, it could be stored in a volume of 1/600. This is the practical way to store it, but the gas must be kept at a temperature of -162 ° C.

Refrigeration

There are several methods for liquefying natural gas in large quantities. One of these is the cooling of natural gas with another gas. Another is regeneratively cooled by continuously passing through a hole until the gas is cooled to degrees at which it liquefies. Expanding cooling of gas through a hole was developed by James Joule and William Thomson. It is known as the Joule-Thomson effect.

Production

The natural gas that goes to the LNG facility is reduced to low temperatures required for storage and treated. For the liquefaction process, natural gas is divided into fractions such as methane, ethane, propane and butane. LNG typically contains more than 90% methane. It also contains small amounts of ethane, propane, butane, some heavy alkanes and nitrogen. The purification process can be designed to give almost 100% methane. One of the risks of LNG is the rapid phase transition explosion (RPT) that occurs when cold LNG comes into contact with water.

The most important infrastructure needed for LNG production and transportation is an LNG facility consisting of one or more LNG trains, each of which is an independent gas liquefaction unit. The largest LNG train in operation is in Qatar with a total capacity of 7.8 million tons per year.

The difference between LNG and LPG

LPG stands for liquefied petroleum gas. LPG is a common energy source used in heating, cooking and lighting. LPG is a colorless and odorless gas. However, the refineries are especially odorized in order to immediately detect a possible leak. LPG It is obtained by refining crude oil in refineries or from natural gas. LPG consists of 70% butane and 30% propane. LPG, which is heavier than air due to its high density, is a flammable gas based on hydrocarbon.

LNG stands for liquefied natural gas. LNG contains 95% methane gas and is cooled to -162 degrees for storage, liquefied and stored.

The most important differences between LPG and LNG;

While light pressure is used to liquefy LPG, LNG is cryogenically liquefied.

LPG is stored, shipped and transported in tanks or cylinders. LNG is stored and shipped in purpose-built cryogenic tanks. Pipelines are often used to transport LNG.

The need for cryogenic storage, along with infrastructure requirements such as manufacturing facilities, distribution stations, and pipeline transport facilities, mean LNG is not a viable option for many developing countries.

The difference between LNG and CNG

CNG stands for compressed natural gas. While liquefied natural gas and compressed natural gas are similar, their distribution and storage methods are different.

LNG is frozen to make it into liquid form while CNG is pressurized to the point where it is very compact. LNG occupies less storage space in a vehicle than CNG and also offers an energy density compared to diesel fuel. This makes it a common choice among many long haul transport companies. LNG can be converted to CNG using appropriate procedures.

On the other hand, it is easier to refuel CNG than LNG, which requires special use and equipment. It has unlimited holding time. Therefore, even if it is not used, there is no fuel loss. This makes CNG the safer choice than LNG. CNG also has lower production costs than LNG.

World’s total production

The LNG industry developed slowly in the second half of the last century. LNG beds were in remote areas where facilities and pipelines could not serve. Large costs were required to treat and transport LNG.

The cost of building a LNG facility is almost at least $ 1.5 billion per 1 billion tonnes of production capacity.

In the early 2000s, the costs of LNG facilities and its shipping fell as new technologies emerged and more investors invested in liquefaction and regasification. There has been an increasing trend to make LNG more competitive as an energy distribution vehicle.

Rising shipbuilding and material prices have put upward pressure on costs over the past few years. The standard price for a 125,000 cubic meter LNG vessel built in European and Japanese shipyards was previously US $ 250 million. When the Korean and Chinese shipyards entered the race, the business changed. Increased competition reduced shipbuilding profit margins and transportation costs, but increased efficiency.

Since 2004, a large number of orders have increased the demand for shipyard slots. It raised prices and increased ship costs.

The construction cost per ton of an LNG liquefaction plant fell steadily from the 1970s to the 1990s. The cost was reduced by about 35 percent. However, recently the cost of building liquefaction and regasification terminals has doubled due to the increased cost of materials and the lack of skilled labor, professional engineers, designers, managers and other white-collar workers.

A new LNG import and export terminal is being designed in many parts of the country, due to concerns of natural gas shortages in the northeast of the USA and / but a surplus of natural gas in the rest of the country.

Global trading

LNG is shipped to all over the world by specially built offshore vessels. The LNG trade is completed by signing a SPA (sales and purchase agreement) between a supplier and the receiving terminal, and signing a GSA (gas sales agreement) between a receiving terminal and end users. Most of the terms of the contract were used as DES or ship delivery, which holds the seller responsible for the transportation of the gas. FOB conditional contracts have increased, with shipbuilding costs low and buyers preferring to secure reliable and stable supplies. Under these circumstances, the buyer who usually owns a vessel or signs a long-term charter agreement with independent carriers is responsible for the carriage.

Click for international commercial terms.

1990’ların ortasında LNG, alıcı bir pazardı. Alıcıların talebi üzerine, SPA’lar hacim ve fiyat açısından bir miktar esneklik benimsemeye başladı. Alıcılar, TOP’da (Take or Pay Contract – Al veya öde sözleşmesi) daha fazla yukarı ve aşağı esnekliğe sahipti ve 16 yıldan daha kısa kısa vadeli SPA’lar yürürlüğe girdi. Kargo ve arbitraj için alternatif varış noktalarına da izin verildi. 21. yüzyılın başında pazar yine satıcıların lehine oldu. Bununla birlikte, satıcılar daha sofistike hale geldi ve şimdi arbitraj fırsatlarını paylaşmayı ve S-eğrisi fiyatlandırmasından uzaklaşmayı öneriyorlar.

Usage

The primary goal of LNG is to facilitate the transportation of natural gas from source to a destination. Large-scale ships become significant when a far away discharging point from the source is to cross an ocean. LNG is usually delivered to the local natural gas pipeline infrastructure at the receiving end. This facility can also be used when there is not enough local pipeline capacity.

LNG is used to fuel internal combustion engines. LNG is in the early stages of becoming the main fuel for transportation needs. It is being evaluated for road transport, maritime and train applications. There are known problems with fuel tanks and the transfer of gas to the engine, but despite these concerns, the transition to LNG as a transport fuel has begun. LNG competes directly with compressed natural gas as a fuel for natural gas vehicles due to its machine similarity. In smaller, isolated communities that do not have access to a local gas source or pipelines, more cost-effective methods can be developed to distribute LNG energy regularly or use it in transport.

Using LNG to fuel large road trucks

China has been a leader in the use of more than 100,000 LNG-powered vehicles as of September 2014.

Public LNG Refueling facilities are implemented in the United States.

In 2015, the Netherlands introduced LNG-powered trucks to the transport industry. The Australian government plans to develop an LNG highway to use locally produced LNG and replace with imported diesel fuel used by interstate transport vehicles.

India made a small start in 2015 by transporting LNG with road tankers powered by LNG in the state of Kerala. Since 2017, Petronet LNG has been building LNG stations along the west coast of India on highways connecting Delhi, Mumbai and Bengaluru to Thiruvananthapuram.

Japan, the world’s largest LNG importer, is preparing to use LNG as road transport fuel.

Use of LNG in marine applications

In some ports, an LNG supply system is set up by road truck tanks to ships. Such LNG fuel operations are easy where an LNG supply is available.

Under the International Convention on the Prevention of Pollution from Ships (MARPOL) adopted by IMO, marine vehicles must reduce emissions. Unlike conventional fuels used by marine vehicles, LNG does not contain sulfur. In this context, LNG is seen as a very good alternative for ships to reduce emissions to 0.

Trading volume

Global trade of LNG is growing globally faster than expected today, beyond levels that were not predicted in the 1970s.

In 1970, global LNG trade was 3 billion cubic meters. In 2011, it was 331 billion cubic meters. The USA started exporting LNG in February 2016. By 2023, the LNG market is estimated to be roughly 13% of the global crude oil market, and this does not include the vast majority of natural gas delivered directly to the consumer by pipeline from the well.

In 2004, LNG accounted for 7 percent of the world’s natural gas demand. Global trade of LNG, which has increased by 7.4 percent annually in the decade from 1995 to 2005, is expected to continue to grow significantly.

Until the mid-1990s, demand for LNG was concentrated mainly in Northeast Asia: Japan, South Korea, and Taiwan. At the same time, Pacific Basin resources dominated the world LNG trade. The worldwide interest in using natural gas-powered combined cycle generation units for electric power generation, combined with the inability of North American and North Sea natural gas supplies to meet growing demand, has significantly expanded regional markets for LNG. It also brought new Atlantic Basin and Middle East suppliers into the trade.

As of the end of 2017, there are 19 LNG exporting countries and 40 LNG importing countries. The top three LNG exporters in 2017 are Qatar, Australia and Malaysia. The top three LNG importers in 2017 were Japan, China and South Korea.

Imports

Japan, South Korea, Spain, France, Italy and Taiwan import large amounts of LNG due to energy shortages. Japan imported in 2005 58.6 million tons of LNG, representing about 30 percent of the worldwide LNG trade. In addition, South Korea imported 22.1 million tons in 2005, and Taiwan 6.8 million tons in 2004. These three large buyers bought around two-thirds of the world’s demand for LNG.

Cost of LNG facilities

Construction cost of LNG projects started to rise rapidly after 2004 and annual capacity was about $ 400 per ton, in 2008 the annual capacity increased to $ 1,000 per ton.

The main reasons for the rapidly increasing costs in the LNG industry can be explained as:

Low availability of engineering, procurement and construction contractors as a result of ongoing extraordinarily high level oil projects around the world.

High raw material prices due to the increase in raw material demand.

Lack of skilled and experienced workforce in the LNG industry.

The very complex nature of projects built in remote locations where construction costs are seen as one of the highest in the world.

Small scale liquefaction plants

Typically they have a compact size, are fed from a natural gas pipeline and are located near where the LNG will be used. This proximity reduces shipping and LNG product costs for consumers. It also prevents additional greenhouse gas emissions that occur during long transportation.

The small-scale LNG plant also balances the availability of natural gas during periods of high and low demand. It also enables communities without access to natural gas pipelines to set up local distribution systems and supply them with stored LNG.

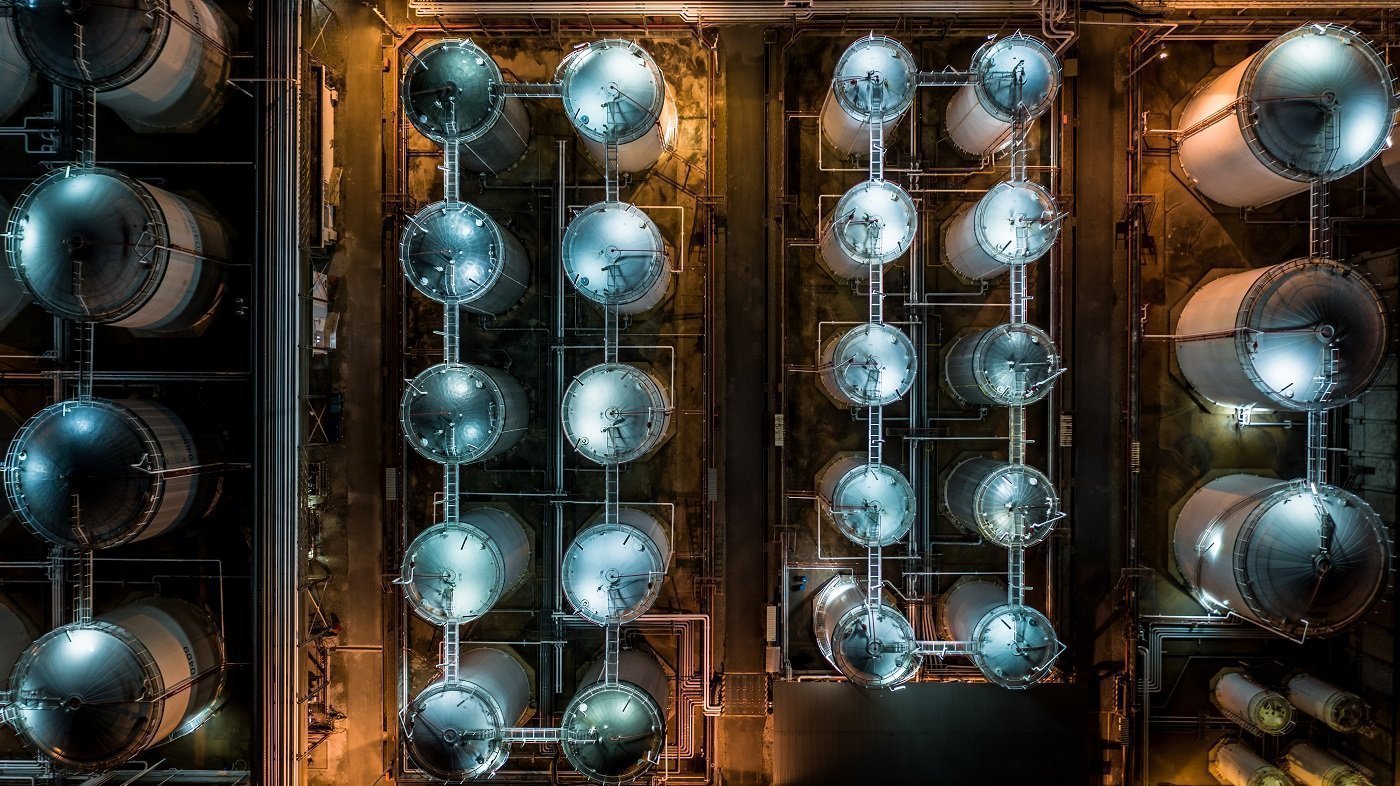

Storage

Modern LNG storage tanks have a concrete outer wall and a steel inner tank with a high nickel content, which provides highly efficient insulation between the walls, typically a full containment type. Large tanks have a concrete roof and a cylindrical design. Domed spherical designs are seen in LNG carriers. The storage pressure in these tanks is very low. Sometimes more expensive underground tanks are used for storage. Smaller quantities (eg 700 cubic meters and less) can be stored in horizontal or vertical vacuum jacketed pressure vessels.

LNG must be kept cool in order to remain liquid regardless of pressure. Despite effective insulation, there will inevitably be some heat leakage into the LNG, which will cause the LNG to evaporate. Evaporated gas is typically compressed and exported as natural gas or re-liquefied and returned to the storage.

Transportation

LNG is transported on specially designed double-skinned ships that protect cargo systems from damage or leaks. There are several specific leak test methods to test the integrity of a LNG ship’s membrane cargo tanks.

Transport and procurement are the most important part of the operation, as natural gas reserves are normally far from consumer markets. Most of the natural gas is transported by pipelines. There is a natural gas pipeline network in the former Soviet Union, Europe and North America. Natural gas travels much faster than oil in a high pressure pipeline, but can only transmit one-fifth of the daily amount of energy due to low density. Natural gas is typically liquefied at the end of the pipeline before transport, converted into LNG and stored.

There are short LNG pipelines for transporting the product from LNG vessels to land storages. Longer pipelines are under development that allow ships to discharge LNG at a greater distance from port facilities. This requires pipe-in-pipe technology due to the need to keep LNG cold.

In addition to land and sea vehicles, LNG is also used in some aircraft.

Terminals

Seaways are generally used for transporting LNG over long distances. In most cases, LNG terminals are purpose built at junction points used solely for LNG export or import.

Environmental concerns

Natural gas can be considered as the most environmentally friendly fossil fuel because it has the lowest CO2 emission per energy unit and is suitable for use in high efficiency combined cycle power plants. For an equivalent amount of heat, burning natural gas produces about 30 percent less carbon dioxide than burning oil and about 45 percent less than coal. Emissions from LNG are lower than those of natural gas on a per kilometer basis. This is a particular problem with the transport of substantial gas in Europe a few thousand kilometers from Russia.

Safety and accidents

Natural gas is a fuel and flammable substance. Special measures are taken in the design, construction and operation of LNG facilities to ensure safe and reliable operation.

LNG in liquid form is not explosive and does not ignite. In order for LNG to burn, it must first evaporate, then be mixed with air in appropriate proportions and then ignited. In the event of a leak, LNG quickly evaporates into gas and mixes with air. If this mixture is in the flammable range, there is a risk of ignition, which could lead to fire and thermal radiation hazards.

Gas leakage from LNG-powered vehicles can pose a flammability hazard if parked indoors for more than a week. Additionally, refueling an LNG-powered vehicle requires training and precaution, due to its low temperature and the risk of freezing.

LNG tankers have traveled over 100 million miles, product-based, with no significant fatalities or even accidents.